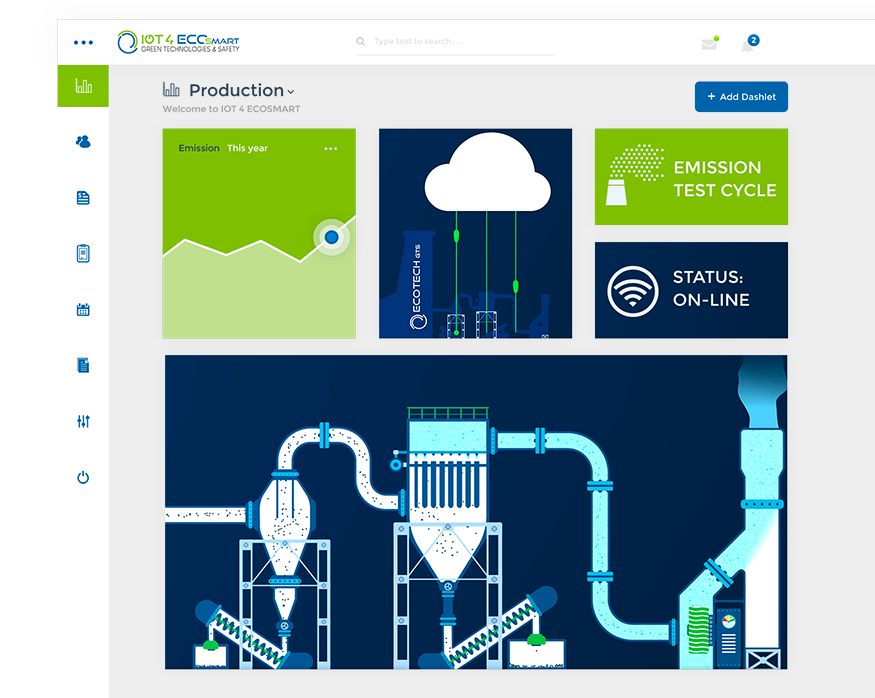

Find out how our Smart 4.0® system works

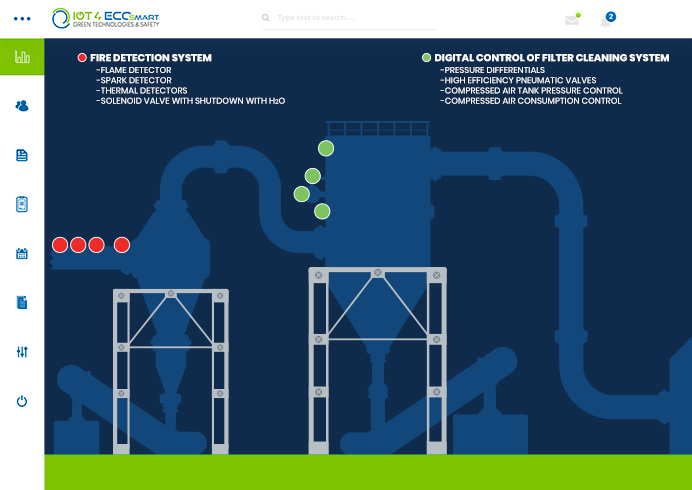

The SMART 4.0® solution is an integrated system designed for the control and supervision of industrial suction and filtering systems.

Click here

FUNCTIONALITY

The platform

in summary

Software

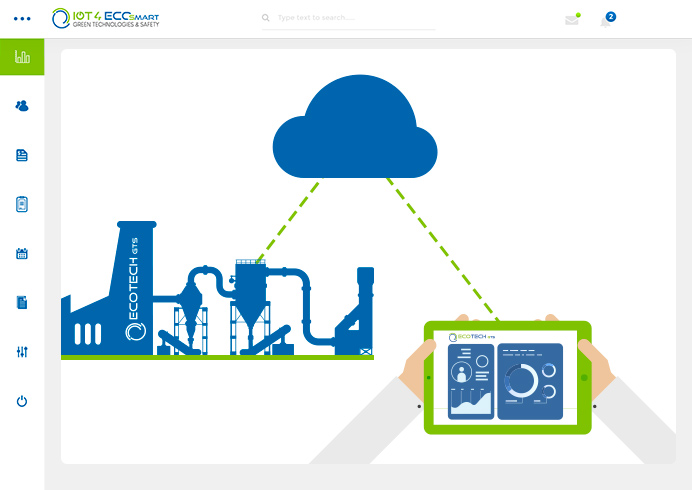

Cloud

Security

Encryption

Firewall

User management

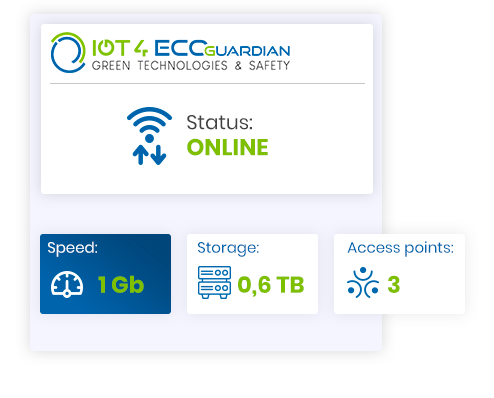

The multi-tiered infrastructure of the IOT 4 Eco Smart cloud-based solution plays an important role in all our remote access solutions. It brings together all network servers, VPN servers and any other services in a secure data area. IOT 4 Eco Smart works with major global hosting partners Tier 1, 2 and 3 to reduce and define latency. Having defined latency is one of the fundamental requirements of Industrial IoT.

What we do in Ecotech Smart

A complete service for electrical panels and

industrial automation systems

Control production, access remotely, improve efficiency, reduce management and energy costs,

receive alarm notifications, schedule maintenance, integrate with corporate IT

01. Why invest in monitoring systems and machines?

Being able to keep an industrial site under control not only means knowing what is happening on each machine or line at all times, but also allows you to use data to improve maintenance processes and increase efficiency. This means eliminating all those wastes that in the past could not be avoided. The latest technologies in this sector allow you to manage targeted maintenance interventions, avoiding both unnecessary replacements and downtime. The costs saved with these types of systems are much greater than you can imagine and consequently there is a return on investment in a short time. Our IOT 4 ECO SMART system is based precisely on these technologies and offers a 360 degree service for all types of needs. The IOT 4 ECO SMART supervision system is a powerful IT platform designed to improve control, optimize efficiency and reduce the costs of a production line. The purpose of IOT 4 ECO SMART is to create a network that allows communication between field devices and remote controllers. Multiple services are also made available to the user, designed to control, analyze and track production; the powerful and intuitive interface can be reached from any remote desktop or mobile device with internet connection. Data collection is carried out via a VPN (Virtual Private Network) connection by connecting the devices in the field to the internet. This connection can be made via wired network, wifi or 3G. The user can access supervision through a web browser, desktop and mobile devices are supported. A secure internet connection is used for this connection. IOT 4 ECO SMART makes available to the user both the data collected from the field and those subsequently processed by the tools of the platform itself.

02. Maximum remote connectivity

Compared to traditional supervision, IOT 4 ECO SAMRT has significant advantages in terms of remote connectivity; access to supervision is possible from various locations such as PCs, smartphones and tablets. User management allows the system administrator to define the different access and operating levels. Multi-user connectivity also allows the use of supervision simultaneously by multiple operators in asynchronous mode.

CONTROL

The IOT 4 ECO SMART platform allows the user to perform a remote control in real time on the status of the system. In particular, it is possible:

View the status of the utilities such as motors, digital pressure switches, filter cleaning control, flow switches, level sensors, star valves, augers, Tribo check probes, solenoid valves, heaters, etc ... (on, off, manual or automatic conditions).

Read physical quantities such as temperatures, levels, speeds, etc.

Change the state of the users or the control regulation set point, if allowed by the credentials assigned to the user who logs in.

View the status of current alarms.

View the status of scheduled maintenance.

MOBILE CONNECTIVITY

Thanks to the mobile function, it is possible to connect to the system from mobile smartphones and tablets.

The user has access to the supervision data in real time, and has the possibility of intervening by making changes from anywhere, if allowed by the credentials assigned.

ALARM HISTORY

The alarm history function allows you to view the alarms that have occurred in the past on the system.

It is possible to search based on a time period or the type of alarm.

The database provides the user with the date and time of alarm intervention, acquisition and recovery by the operator.

EMAIL NOTIFICATIONS

It is possible to receive e-mails and text messages in real time for the notification of conditions related to production lines or production progress, for example:

Alarm or pre-alarm status.

Anomaly status on production parameters such as cycle times, speed, temperatures

Component change request

Request for intervention by an operator

The notifications are scheduled in a totally "custom" way according to the customer's requests. Different types of sending logics can be configured:

With priority based on the type of report.

APPLICATION SECTORS

Air filtration and suction systems

Heating, air conditioning, air treatment.

EMISSIONS

Some data - Total greenhouse gas emissions

Methane, diesel, LPG

Electric energy

Incinerator

Landfills

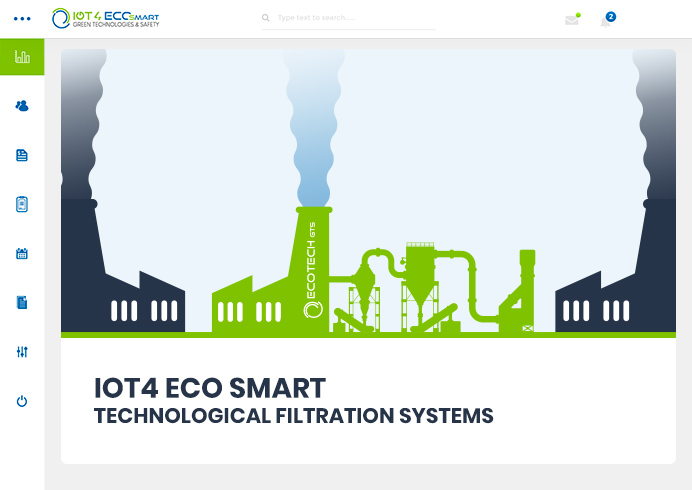

Video IOT4 ECO SMART

Management, monitoring and remote control of technological systems for filtering and purifying air from dust from industrial and artisan processes.

Control production by monitoring all the components of your system from a single panel, improve efficiency, reduce management and energy costs, all with a low environmental impact.

Applications to control emissions into the atmosphere

Continuous monitoring systems,

locally and remotely, on emissions

in the atmosphere.

EU and / or national legislation provides for the presence of continuous emission monitoring systems (S.M.C.E.) or atmospheric emissions analysis systems (S.A.E.) for certain types of plants.

01. Checks on emissions into the atmosphere

Arpa carries out direct and indirect controls on emissions into the atmosphere, conveyed and diffused, generated by plants where there are authorized plants in order to verify both compliance with the limits set for the substances issued and the requirements indicated in the authorization documents, assessing the compliance of the self-control operations as well as the environmental management of the plants that produce emissions. Arpa verifies and controls the conditions of air pollution possibly reported by public and private subjects.

02. Control of emission sources into the atmosphere

This control is declined at the level of activity in the sampling field and measurement at the chimney and documentary checks; the activities are scheduled on the basis of the environmental load connected to the activity carried out, the presence of dangerous substances, the existence of critical issues already encountered in the past, the lack of controls in the medium term. Arpa checks thousands of people responsible for emissions into the atmosphere every year. The Agency also intervenes, even in ready availability, in cases of reported criticality for the atmospheric sector attributable to emissions. The Agency's control is widespread and widespread in the area of competence and affects both traditional pollutants and organic and non-organic pollutants, based on the same criteria of efficiency and homogeneity.

03. Check validity and compliance of self-checks

The verification of the self-control activities follows the communications of the Companies in relation to the initial or periodic self-control phases of emissions, favoring logics that take into consideration the environmental load attached to the activity carried out, the critical issues related to certain production activities and the differentiation between sectors different. In this context, the control activity carried out directly in the field, at the time of self-control, on new emission points or on existing plants with high environmental significance is generally privileged. The type of control in question is particularly effective in disseminating and advocating the concepts of good practice, professionalism and reliability in the practices of self-certification of compliance by those responsible for emissions into the atmosphere.

ECOTECH GTS SRL

offers innovative high-tech solutions for Biofilm monitoring

The technology proposed by ECOTECH-GTS is currently used all over the world and every day helps the Technical Staff responsible for cleaning and sanitizing treatments, in different industrial sectors, in the optimization of these procedures and in the prevention of problems related to the growth of biofilm, from bacterial corrosion (MIC) to Legionella risk.

Who we are

Our brands